Paul Kochendörfer

The label was creased up at the place where the year was handwritten. But according to the owner, it's pretty old. I have been reading about guitars made by violin makers, when this Paul Kochendörfer came in, in a very sorry state.

From the tall saddle, it suggest a "reverse" neck angle.

I'll explain it further, read on...

It's heart wrenching to see such damage to a well made instrument.

I actually found a replacement bridge, but I was hesitant to slap a new bridge on a vintage.

The back of it seems hopeless, especially when it broke squared at one of the wings

I lined up the cracks with much diligence as precisely as possible. You cannot rely on glue for structure, unless it has perfect mating surface to bond with.

It looks war torn, but pretty complete from the top

With offcuts from my earlier build, I began to fill in the gaps...

...here a big chunk was missing at the wing...

...being glued on...

...gives me ample material to remove...

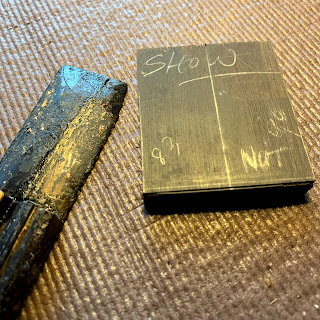

...with the bottom gaps fill tight with ebony dust and glue, the bridge was sanded and polished to high gloss to remind of her glorious past

Sure enough, after reconstructing the bridge, I checked the neck angle

and found it to have "reverse" neck angle issue.

You see, when you place a straight edge on the frets,

the ruler should touch halfway the height of the bridge.

Here, it clearly touches the top.

This is neck angle is suitable for steel string guitars, not classical nylon...

...otherwise, the guitar would need a really tall saddle for the playing string to clear the frets without string buzzes. The taller the saddle, the greater the string break angle (see the string in red sloping to the tie hole). The greater the break angle, the more volume you get. But too great a break angle, could pull the bridge beyond what it could tolerate. This may well caused the bridge to disintegrate!

This would be a healthy reading, but being build with a Spanish heel, it's impossible for a neck reset. The only way around this would be to have a taller bridge. A temporary shim suggest how much taller it needs to be...

It needed 6 x walnut veneer shims of 0.5mm!

So off to gluing up...

...it's messy again

...shaping the veneers to fit the bridge...

...so they can live harmoniously...

Gluing surfaces needed to be cleaned and matched in the correct radius

Ready for glue up

Glue up

The saddle can now be shaved lower for a shallower break angle,

so the bridge can last for another hundred years.

I hope.

Completed

These were the original tuners.

Beautiful.

But this side has faulty gears, all clogged up with glue or something, which is impossible to turn. No wonder the buttons gave way.

These vintage has a narrower tuner post spacing than the standard 35mm now.

Off to the drawing board for a detailed drawing for the machine head maker to replicate.

Boom!

The tuner posts were slight large. Had to enlarge the holes for a perfect fit.

They turn very well after that.

Hauser styled tuner plate

The fret condition was mostly ok except for some loose frets and sharp fret ends on the entire fretboard.

But they were easily dealt with.

After

The resultant action after the correction of height at the bridge.

The guitar is solid enough to take this low action, without much buzz!

Sweet.

Restored